Farmers rely heavily on machinery like tractors, plows, and harvesters. These machines are often exposed to harsh outdoor conditions, including salt from fertilizers and brine solutions used for de-icing roads in winter. Over time, this exposure can lead to corrosion, reducing the lifespan of expensive equipment and increasing maintenance costs.

Salts Gone® is an instantly acting chelating agent for salt/brine. There are 3 primary components to it:

- Chelating agents for the various forms of salt

- Corrosion inhibitors to prevent future salt from causing further damage

- Surfactants (soap)

Salts Gone® is:

PH Neutral

- This means it's safe to use on any material you would find on a vehicle, including metals, glass, paint, ceramic coatings, wax, vinyl wraps, etc. It's even safe to fall on your landscaping, making it hassle-free and easy to use.

Highly Concentrated

- Each gallon makes one hundred gallons of finished solution (1:100)

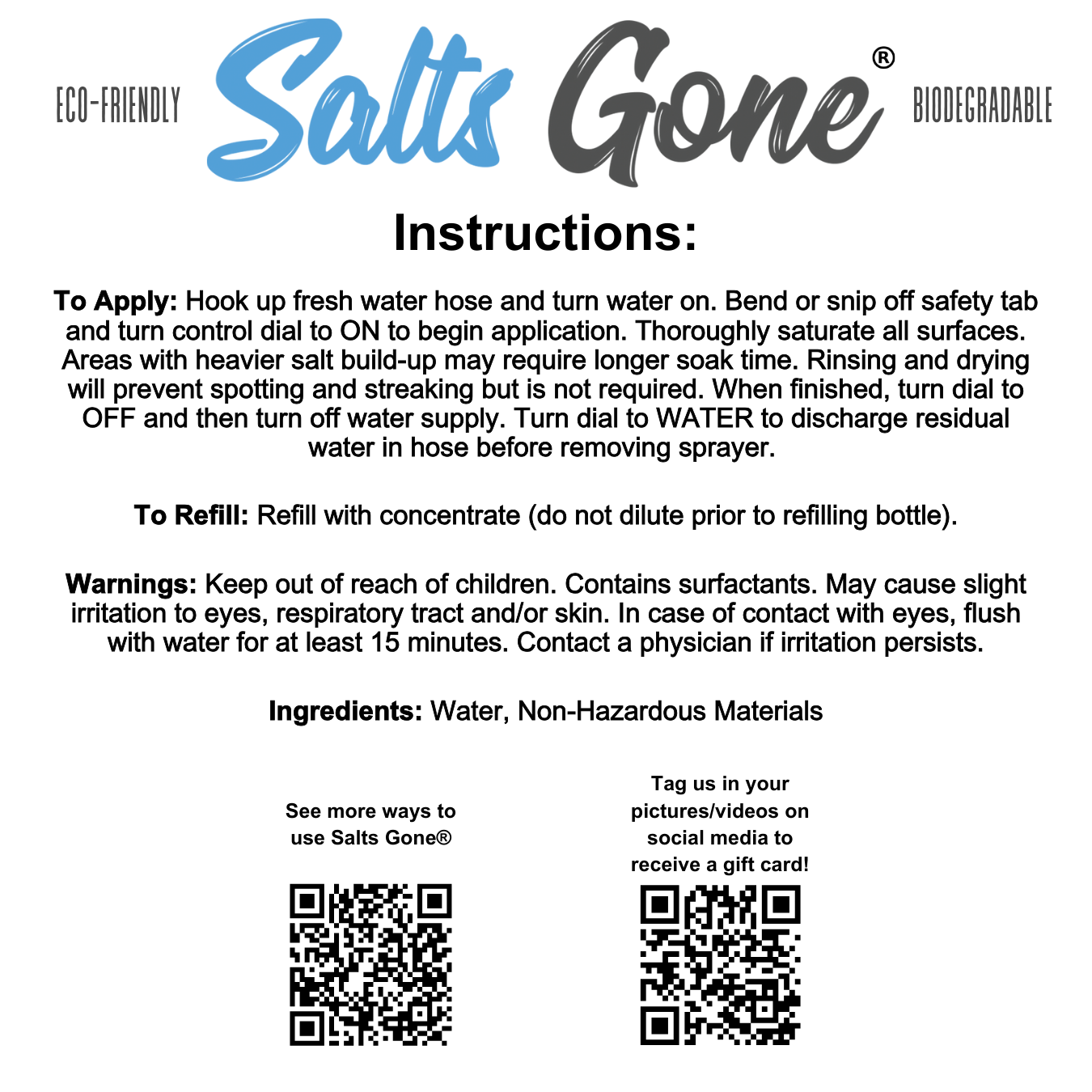

Can be applied with or without running water

- With running water: Hose End Sprayers, injector boxes, pressure washers

- No running water: Pump Sprayers, Battery operated sprayers

Salts Gone® does not emulsify oil

- This means it's safe to use with any undercoating product

The impact of corrosion in the agricultural sector extends far beyond mere surface damage. It manifests as a multifaceted challenge, causing a ripple effect that touches upon various aspects of farming operations.

- Decreased Equipment Efficiency: Corroded equipment doesn't function as efficiently as it should. Rust and corrosion can affect moving parts, reducing performance and causing equipment breakdowns. This can lead to downtime during crucial planting and harvesting seasons, resulting in financial losses.

- Safety Hazards: Corrosion can compromise the structural integrity of farm infrastructures such as barns, silos, and storage tanks. This poses safety risks to both livestock and farm workers. Weakened structures may collapse, potentially causing injuries or fatalities.

- Financial Burden: Constantly repairing or replacing corroded equipment and infrastructure can be a significant financial burden for farmers, especially small-scale operators. It can affect their overall profitability and sustainability.

- Maintenance Costs: Farmers often spend a considerable amount of time and money on maintaining and repairing corroded equipment. This detracts from other important tasks on the farm.

These are only a few of the problems that salt and rust continue to cause. Ultimately, addressing and mitigating the corrosive challenges in agriculture is not just a matter of maintenance but a crucial step towards securing the future of farming, ensuring its efficiency, safety, and environmental responsibility. That's where Salts Gone® comes in.

How Salts Gone® will help YOU

Salts Gone® offers a transformative solution for tackling salt-induced corrosion on farm equipment. Its ease of use, remarkable effectiveness, and proud American production make it an invaluable asset for agriculture. By simply diluting this concentrated product with water, or using our hose end sprayer which dilutes it for you directly into your hose stream, and applying it to affected areas, farmers can rejuvenate their equipment, shielding it from the corrosive effects of salt and ensuring prolonged functionality. With Salts Gone®, you're not just addressing corrosion; you're also safeguarding your agricultural investments and extending the lifespan of vital machinery, ultimately enhancing the efficiency and productivity of your farm operations. Discover the power of Salts Gone®, and fortify your farm equipment against the corrosive challenges of the agricultural environment.

Addressing Already Rusty Equipment

While Salts Gone® effectively combats salt-related corrosion in farm-equipment, another indispensable ally in the fight against rust and corrosion is Rusts Gone. This rust converter offers a seamless transition from protection to restoration, ensuring that your farm equipment remains in peak condition. When your equipment is already affected by rust, Rusts Gone fights already existing rust by converting ferrous oxide into ferric oxide, leaving a primed and protected surface.

Before Rusts Gone